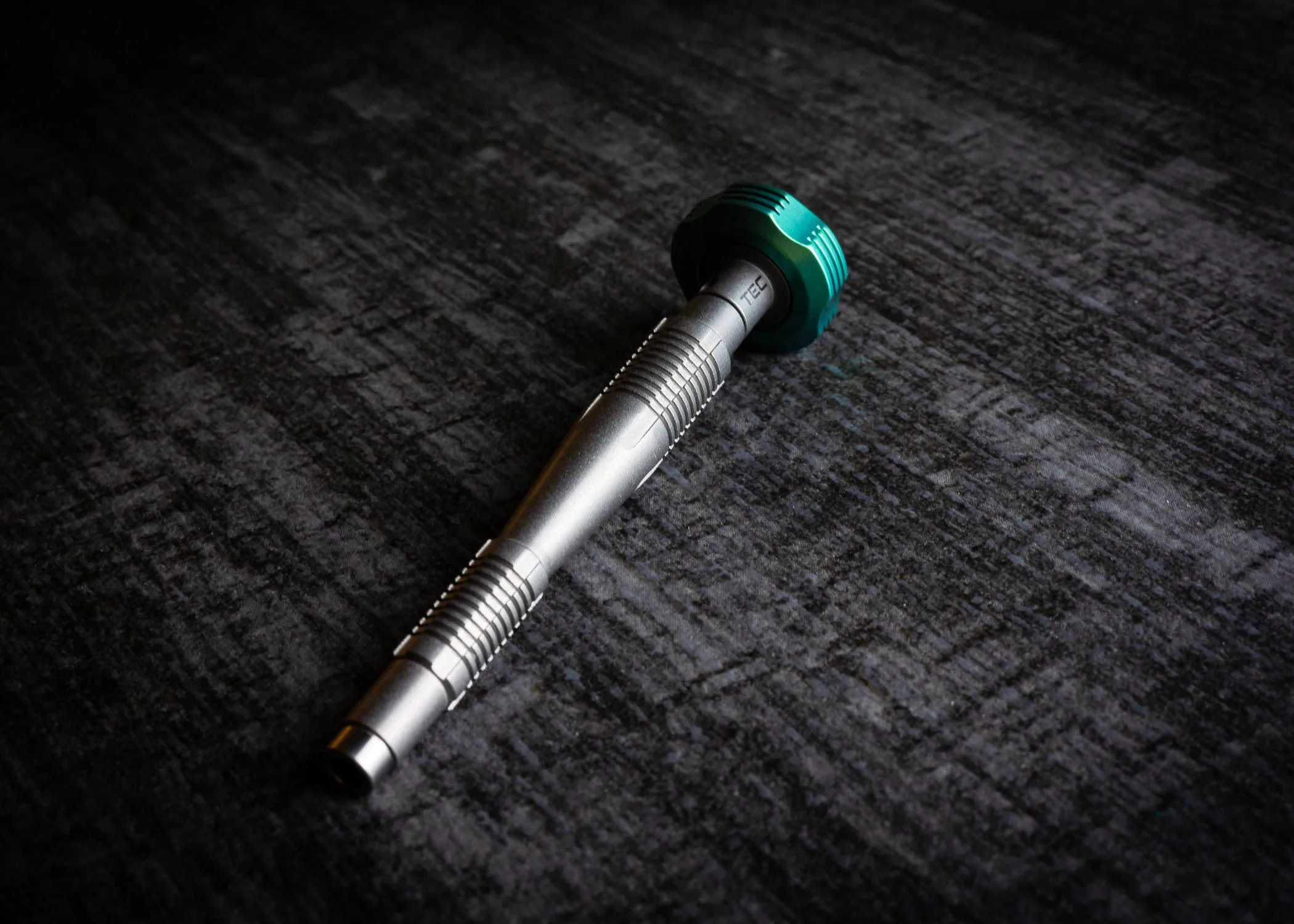

The Micro-Torq titanium 4mm hex bit driver is the perfect tool for your routine chores, special DIY projects, and maintenance tasks. Based on the readily available 4mm micro bit standard, the Micro-Torq is a pleasure to use whether it's once a day or one hundred times a day. It's everything you would want in a hex bit driver and more. Key features include:

- Magnetic bit retention

- Precision ball bearing mounted end cap

- Dual knurled regions for the perfect grip during palm or fingertip use

- Full titanium construction for light weight and ultimate durability

- Torq Bar for increased rotational torque

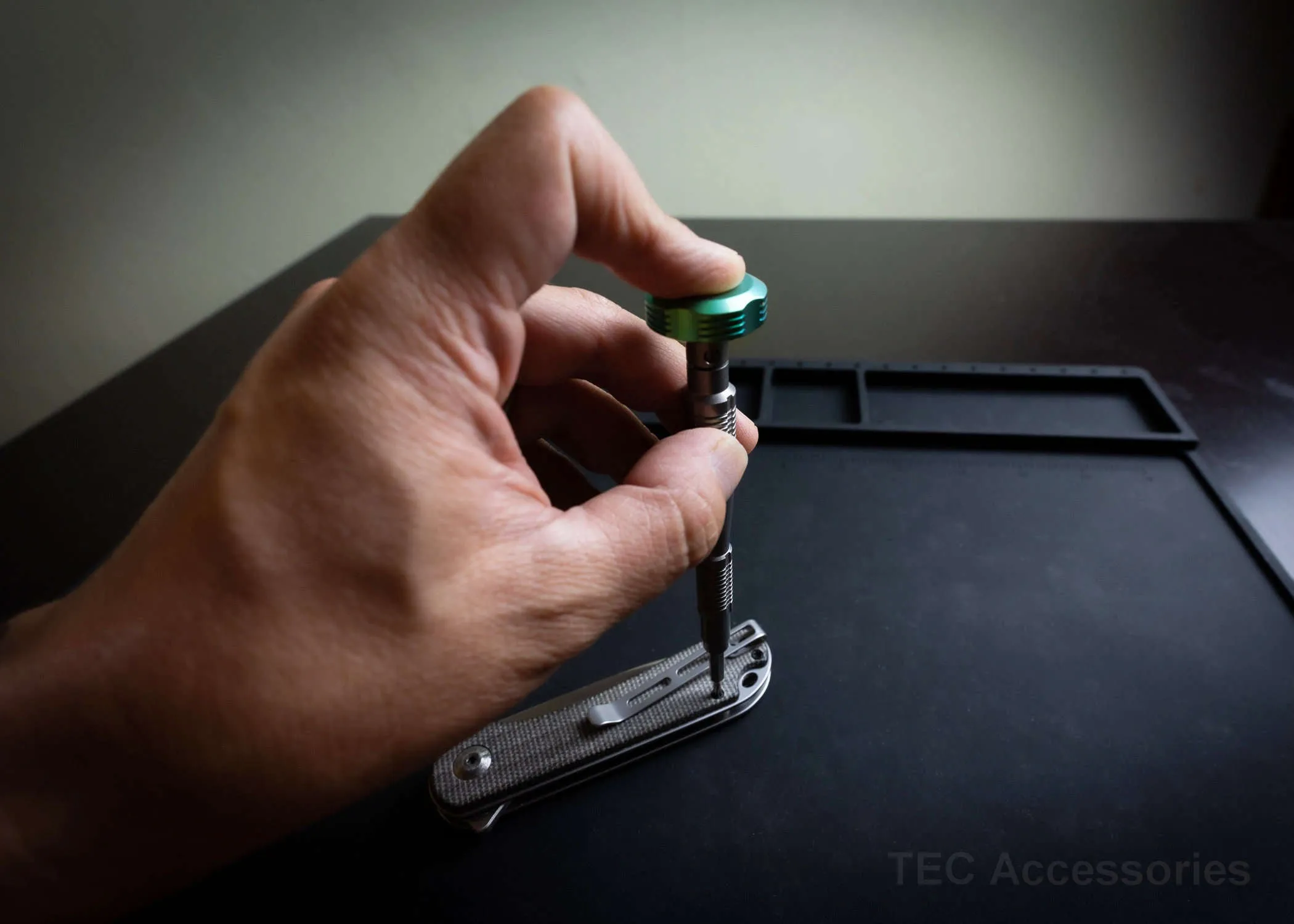

Using the 4mm hex bit format, the Micro-Torq can leverage a smaller, thinner and lighter overall package than other 1/4" hex bit drivers, yet still provide just as much muscle and durability. The included Torq Bar acts like a T-wrench handle, providing a firm grip to easily release those rusted, stubborn screws without reaching for a larger tool. Simply insert it through the matching holes in the body and the bearing mount, and you have instant increased torque capability.

Our unique dual knurl pattern prevents finger slippage in both rotational and linear axes, with a smooth transition between the two sets to ensure a precise and comfortable grip during use. Positioned for the utmost comfort, you can rest the end cap in the palm of your hand or steadied with your index fingertip and always have a firm grip within reach.

Utilizing an ABEC-7 precision ball bearing in the end cap, you can freely rotate the barrel of the driver without the need to overcome the force against of your palm or fingertip. Smooth, flowing motion with extremely low friction. For virtually zero friction and that "fidget spin" capability, you can upgrade to our user-replaceable . We have achieved end cap spin times of over 3 minutes with this bearing!

Ensuring a lifetime of dependable service, the bearing cap is user-removable in case you ever need to replace the bearing, upgrade to our ceramic bearing, or even want to replace the cap with a different color or style. Inserting the Torq bar through the matching holes in the body will lock the bearing in position, allowing you to simply unscrew the cap from the bearing mount. Nothing complicated, just common sense design.

Available in 3 anodized cap colors, choose your favorite and throw away all those other inferior drivers in your tool box!

What you get:

- [1] Micro-Torq 4mm Hex Bit Driver

- [1] Torq bar

Please note: This product does not come with hex bits. 4mm micro bits are available from many online sources including .

Ceramic bearing upgrade is available

Specifications

Body Dimensions:

- Length (without hex bit: 4.13" [105.0 mm]

- Length (with hex bit): Approximately 4.98" [126.5 mm]

- End cap diameter: 0.98" [25.0 mm]

- Body diameter at large knurling: 0.47" [12.0 mm]

- Body diameter at small knurling: 0.37" [9.5 mm]

Materials:

- Body, bearing mount and end cap: 6Al-4V titanium (Grade 5)

- Bearing: Chrome Steel

- Bearing Shoulder Screw: 316 Stainless Steel

Weight (without hex bit): 1.66 oz [47 grams]

Finish: Driver body is bead blasted to a uniform matte finish. end cap is anodized in your choice of 3 colors: Aqua, Green, and Blue Raspberry

Hex Bits (not included):

- Bit engagement depth: Approximately 0.236" [6.0 mm]

- Magnetic retention: Neodymium magnet

- Hex bit size: Industry standard 4mm

Finishing

The Micro-Torq driver components are run through a series of strict finishing processes to ensure repeatable results on every production run. This not only ensures consistent quality, but it also provides you with a superior product that you will be proud to own:

- The driver bodies and bearing housings are masked and bead blasted by hand to ensure a uniform finish

- The bearing housings are laser engraved with a subtle TEC logo, verifying that you receive a genuine TEC product

- The end caps are tumbled through a 4-stage process over the course of 8 days, resulting in a highly polished surface finish. This will provide a brilliant color intensity after anodizing

- The caps are then thoroughly inspected and run through an ultrasonic cleaning bath to prepare them for anodizing

- The titanium anodizing performed on the caps is done using a tightly controlled electrical voltage process to ensure repeatable color from batch to batch

The above steps, in addition to all of our intermediate inspection and quality checks, guarantee that you will receive the best possible product TEC Accessories can produce.